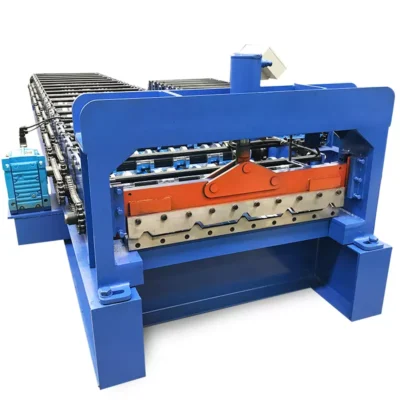

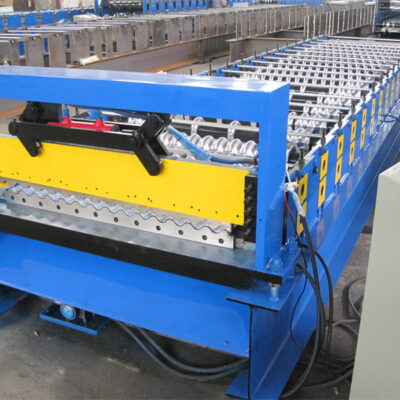

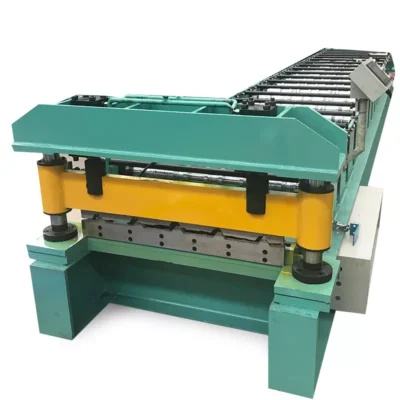

Ridge Cap Roll Forming Machine

Ridge cap roll forming machine is mainly used to produce ridge cap which is always work with roof tile panels. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

Roofing system roll forming machine has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile, glazed tile, metal deck, wall panel, standing seam, K span and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.