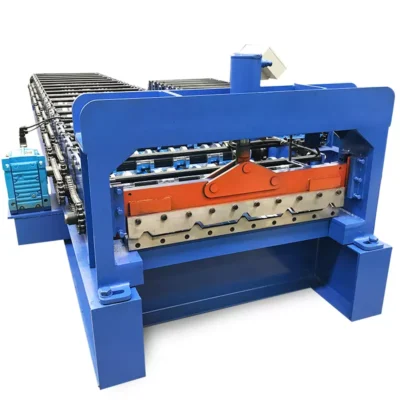

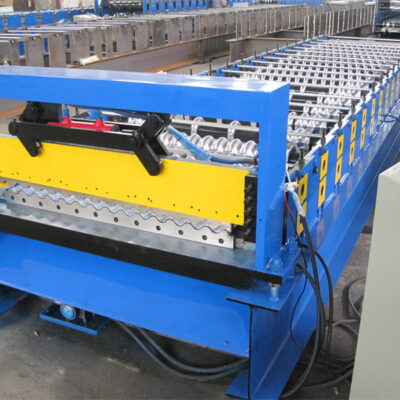

Roof Panel Double Layer Machine丨Tile &

Features Tile & roof panel double layer machine can produce Tile sheet and roof sheet according to the client’s profile drawings and requirements. The steel trapezoidal sheets are new building materials with various thickness and colors. Applications The finished products are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition…