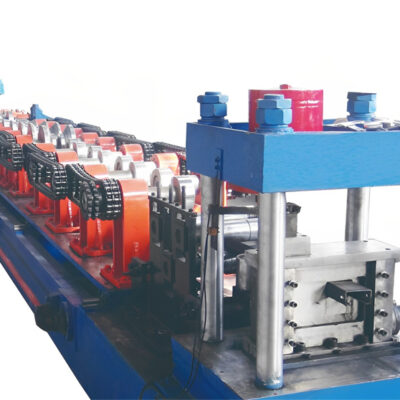

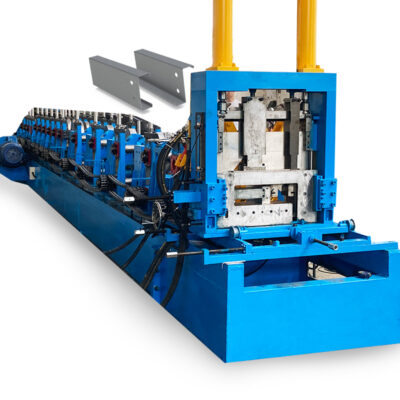

Auto Changeable C Z Purline Machine

SUNWAY design this auto changeable C Z purline machine to work with any size of the purlin, automatically adjustable sizes on PLC. Whats’ more, changing time from C to Z only need 5-10 minutes. Regarding the punching unit, we can design pre punching, post punching according to your requirement. For cutting unit, you can choose the pre-cut or post-cut which is universal cutting. The driving system we adopt the chain and mostly with gimbal /gearbox for transmission if the raw material is thicker than 2.5mm, this is much more strong driving power and more stable when forming the purlins.