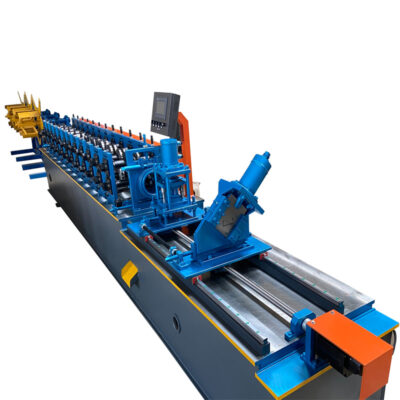

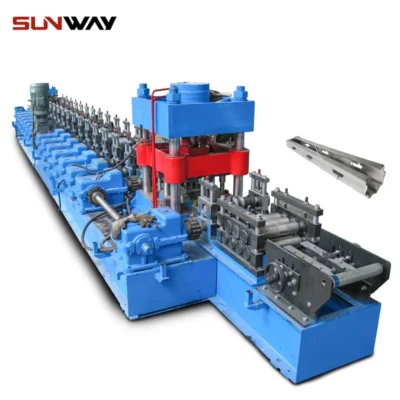

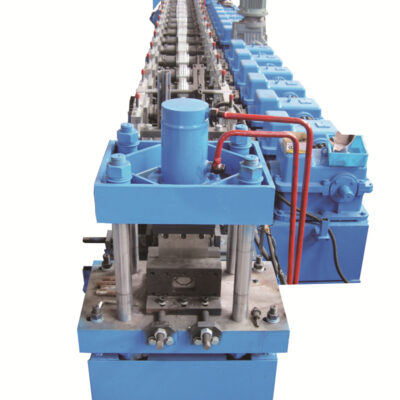

L Angle roll forming machine

L Angle roll forming machine Summary Material: HR, CR steel, GI steel Material Thickness: 0.5-1.6 mm Main Power: 5.5 KW Forming Speed: 10-15m/min L Angle roll forming machine Main Parts Manual Decoiler Feeding Guide Roll Forming System Hydraulic Cutting Hydraulic Station PLC Control System Run-out Table Working Flowing Decoiler— Feeding— Roll Forming —- Cutting —- Run…