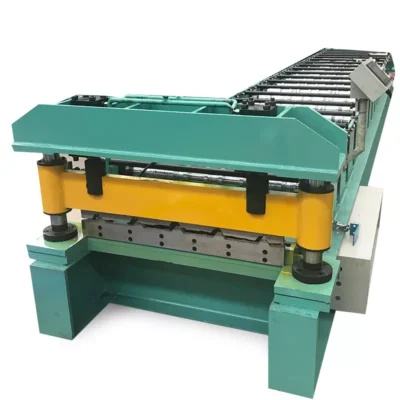

2 profile in 1 roll forming machine

Global Service

Our professional foreign traders will satisfy global businessman as customers' will.

Design & Create

There are 20+ experienced engineers here to design various components.

QC & QA

Each step of production process is carried out in strict accordance with ISO standards.

Share This Product

Description

2 profile in 1 roll forming machine Summary

- Material: Color steel, Galvanized coil

- Material Thickness: 0.4-1.5mm

- Forming Speed: 10-15m/min

2 profile in 1 roll forming machine Main Parts

- Manual Decoiler

- Feeding Guide

- Roll Forming System

- Hydraulic Cutting

- PLC Control System

- Run-out Table

Working Flowing

Decoiler— Guide–Roll Forming—- cutting–Run out table

2 profile in 1 roll forming machine Technical Data:

1). Manual Decoiler

- * Decoiler Type: Manual Decoiler

- * Weight Capacity Of Decoiler: 3 Ton

- * Inner Diameter. Φ460-520mm

- * Outer Diameter. Φ1400mm

Reference picture:

2). Roll Forming system

- Axis Diameter:60 mm

- Forming Roller stand: 10-12Groups

- Main Axis material: First grade 45# steel, heated and quenched

- Roller material: First grade 45# steel, with hard chrome 0.05mm, Quenched and heated process

- Drive Type: 1” Chain of transmission

- Chain material: 45#steel, HRC45-50

- Machine Frame stand: Welded structural steel

- Main motor Power: 5.5 KW

Reference picture:

3) Cutting Device (include 2 size)

- Cutting type: Hydraulic cutting

- Hydraulic pump station power: 4 KW

- Hydraulic pressure: 12Mpa

- Hydraulic Blade and cutter material: Cr12, quenching process 58-62

- Cutting length tolerance: 10M+/- 2.0 mm

Reference picture:

4). Electrical System

- Voltage: 380V, 3 Phase 50Hz

- PLC Electrical control system: PANASONIC

- Length Controller: Encoder Frequency Control System

- Operation: Touch Screen

- Transducer: Japan YASKAWA

Reference picture:

5) Runout Table

- Non-power type

- Quantity:2

fAQ

We are factory with professional production team and service consciousness just for exporting various types of laser machine.

Yes, we are available online to give guidance and also have skilled technicians to dispatch to customers’ factories.

30% deposit is paid before production, the balance paid after inspection confirmation before shipment.

The quality of our machines is very reliable. The warranty is one year after delivery, if some parts are broken, we will send you new ones for free and customer affords the express cost. If some parts are broken out of warranty period, we will sell them at cost.

Yes, we will. The core of our company culture is honesty and credit. Sunway is ALIBABA’s Gold supplier with BV assessment and CE certificate.

No, most of our machines are designed according to customers’ specifications, using famous brand components.

Fly to Shanghai airport: By high speed train from Shanghai to Wuxi (30 min),then we can pick up you.

Table of Contents

Inquiry Now

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message. 🙂

Reviews

There are no reviews yet.