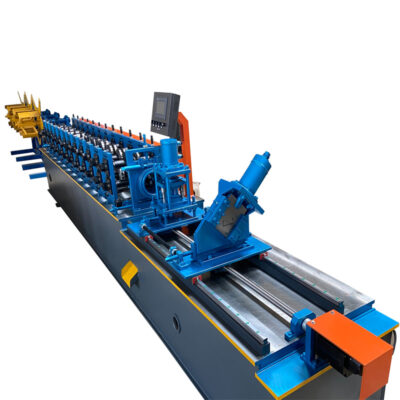

Laser Welding Square Pipe Roll Forming Machine

Laser welding square pipe roll forming machine is to produce different sizes of square pipes or tubes which can be used as purlins on metal building system. Compared with high frequency welding tube line, this machine is cheap, occupy smaller space, easier to operate. It is much suitable for the business starting.

Global Service

Our professional foreign traders will satisfy global businessman as customers' will.

Design & Create

There are 20+ experienced engineers here to design various components.

QC & QA

Each step of production process is carried out in strict accordance with ISO standards.

Share This Product

Description

Laser welding square pipe roll forming machine is to produce different sizes of square pipes or tubes which can be used as purlins on metal building system. Compared with high frequency welding tube line, this machine is cheap, occupy smaller space, easier to operate. It is much suitable for the business starting.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine, corrugated roll forming machine, ridge cap roll forming machine, downspout roll forming machine, etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

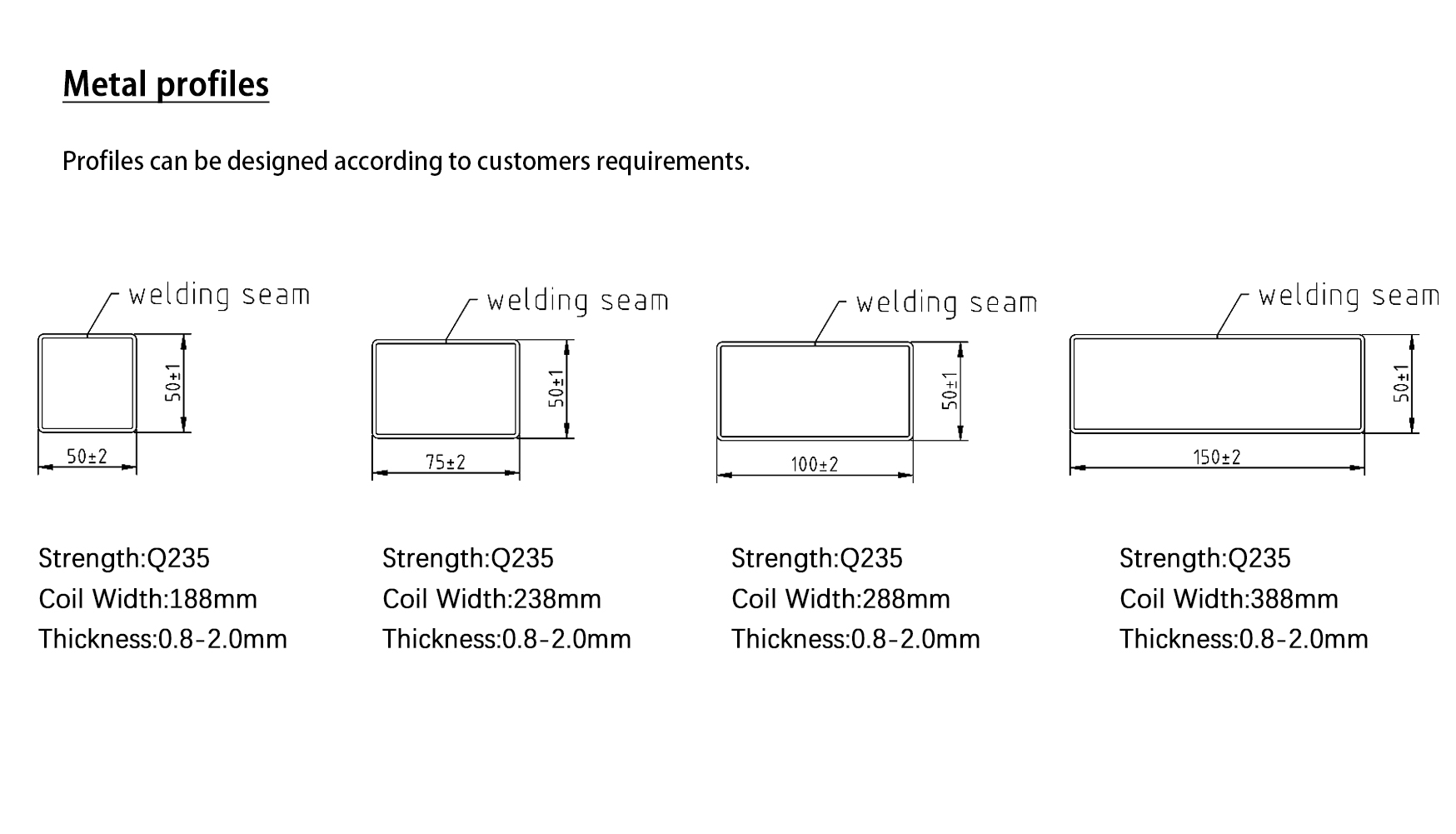

Profile Drawings

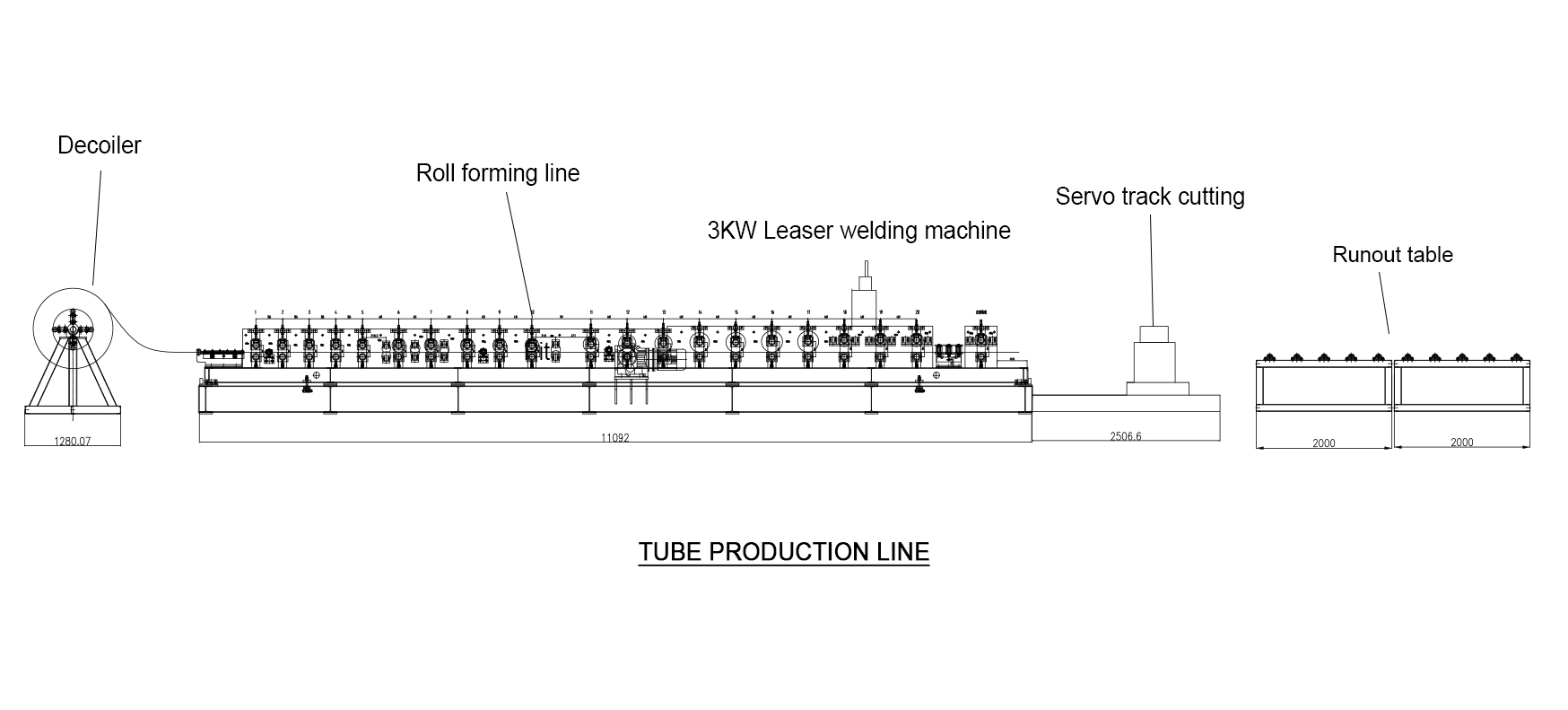

Production Line

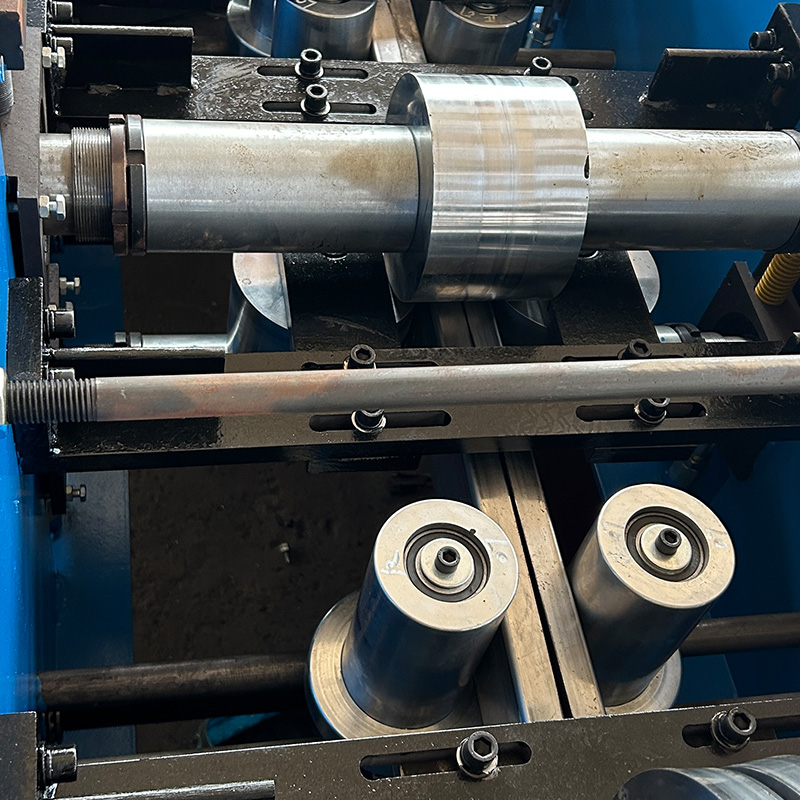

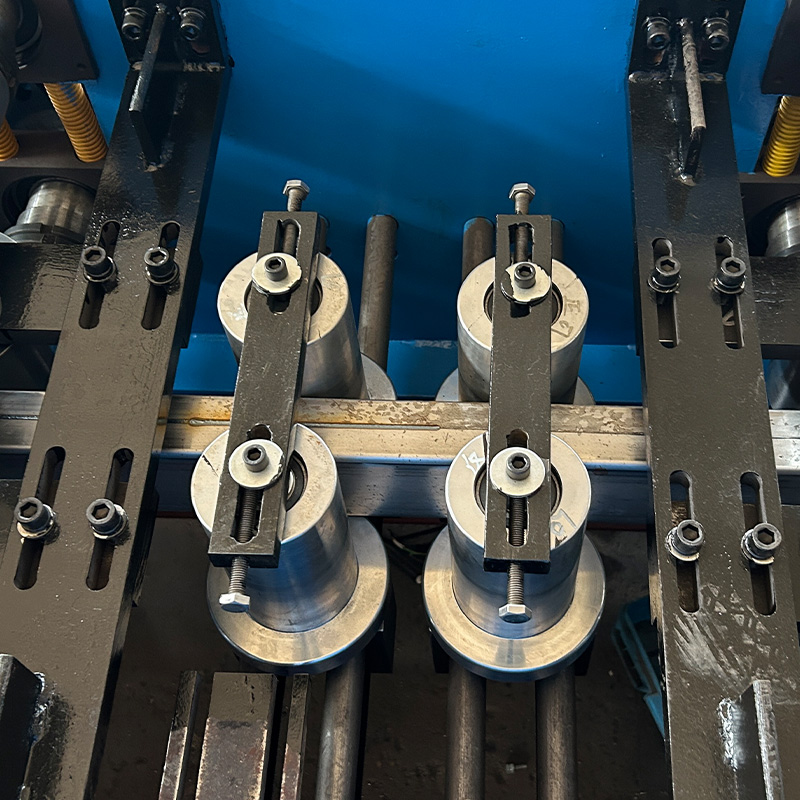

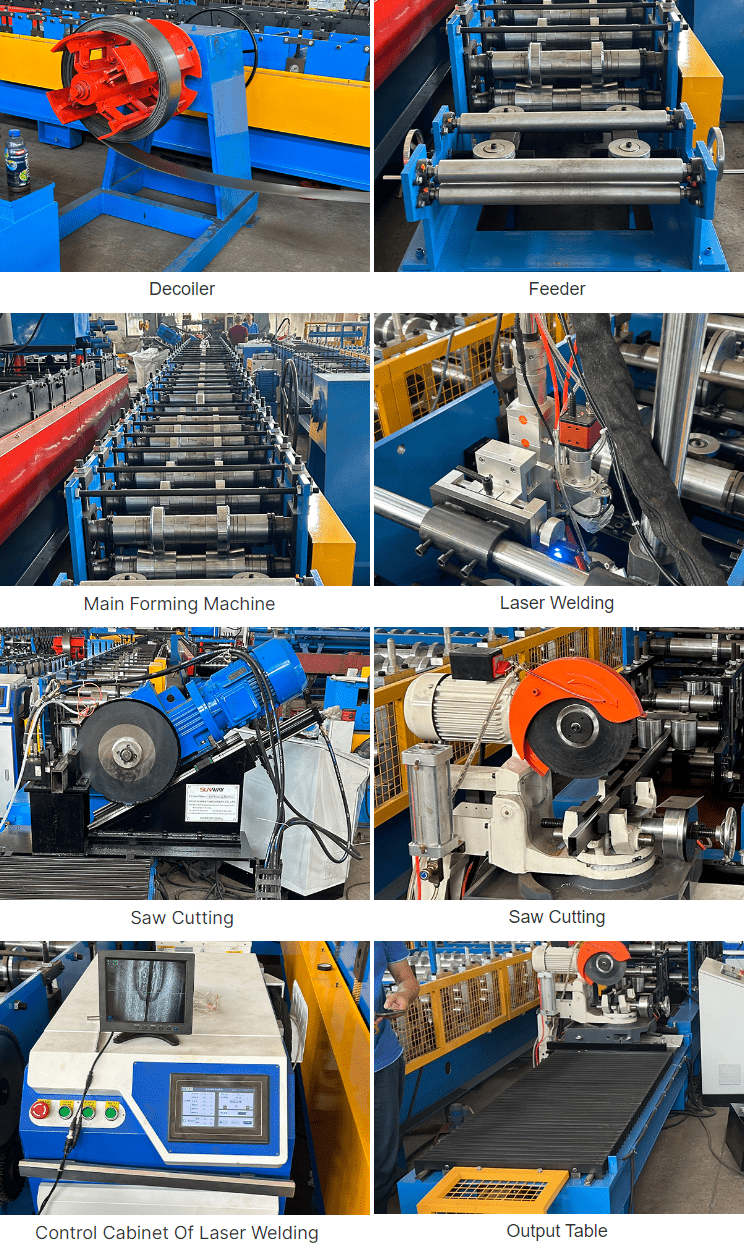

Product Details

Product Parameters

| Laser Welding Square Pipe Roll Forming Machine | ||

|

Raw Material

|

A) Galvanized Coil |

Thickness(MM): 1.5-3.0 mm Or According To Customer

|

| B) Carbon Steel Coil | ||

| Yield Strength | 250 – 550 Mpa | |

| Tensil Stress | G250 Mpa-G550 Mpa | |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Forming Station | 16-24 Stations | |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Wall Panel Station | * Forged Iron Station (Optional) |

| Forming Speed | 10-25 (M/MIN) | * According To Your Profile Drawings |

| Rollers’ Material | 45# Steel | * Cr12Mov (Optional) |

| Laser Welding | 3KW, 4KW | |

| Cutting System | Saw-cutting | |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| PLC Brand | Panasonic | * Siemens (Optional) |

| Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

fAQ

We are factory with professional production team and service consciousness just for exporting various types of laser machine.

Yes, we are available online to give guidance and also have skilled technicians to dispatch to customers’ factories.

30% deposit is paid before production, the balance paid after inspection confirmation before shipment.

The quality of our machines is very reliable. The warranty is one year after delivery, if some parts are broken, we will send you new ones for free and customer affords the express cost. If some parts are broken out of warranty period, we will sell them at cost.

Yes, we will. The core of our company culture is honesty and credit. Sunway is ALIBABA’s Gold supplier with BV assessment and CE certificate.

No, most of our machines are designed according to customers’ specifications, using famous brand components.

Fly to Shanghai airport: By high speed train from Shanghai to Wuxi (30 min),then we can pick up you.

Table of Contents

Inquiry Now

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message. 🙂