When it comes to construction safety, scaffolding walk boards play a crucial role. These boards provide workers with stable platforms to perform tasks at heights, ensuring both safety and efficiency. But have you ever wondered how these durable, anti-slip boards are manufactured with such precision? The answer lies in the İskele Yürüme Tahtası Rulo Şekillendirme Makinesi—a technological marvel designed to produce high-quality walk boards with speed, accuracy, and efficiency.

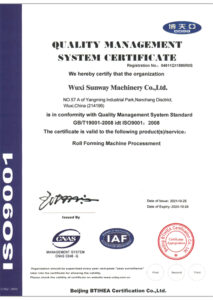

Bu kapsamlı kılavuzda, aşağıdakiler hakkında bilmeniz gereken her şeyi keşfedeceğiz Scaffolding Walk Board Roll Forming Machines, their applications, key features, pricing, automation advancements, and why Wuxi Sunway Makine is the industry’s go-to manufacturer for roll-forming equipment. Let’s dive in!

What is a Scaffolding Walk Board Roll Forming Machine?

A İskele Yürüme Tahtası Rulo Şekillendirme Makinesi is a specialized piece of equipment designed to manufacture metal planks or walk boards used in scaffolding systems. These machines shape flat metal coils into boards with perforations for anti-slip surfaces, reinforced edges for durability, and precise dimensions to meet industry standards.

Sunway'in Scaffolding Walk Board Machines are engineered to deliver exceptional efficiency, consistency, and quality, making them the ideal choice for manufacturers aiming to produce walk boards at scale.

Applications of Scaffolding Walk Boards

Scaffolding walk boards are essential in industries where height-related tasks are common. Their robust design and anti-slip properties make them indispensable for various applications:

1. İnşaat Sahaları

Scaffolding walk boards provide a safe and stable platform for workers performing tasks such as plastering, painting, and masonry work.

2. Endüstriyel Bakım

Factories, power plants, and warehouses use scaffolding walk boards for equipment installation, repairs, and maintenance.

3. Gemi İnşaatı

In shipyards, walk boards are used to provide access to hard-to-reach areas for welding, painting, and assembly tasks.

4. Oil and Gas Industry

Refineries and offshore platforms rely on scaffolding walk boards for their durability and slip-resistant properties, even in harsh environments.

5. Event Setup

Temporary event setups, such as stages and seating arrangements, utilize scaffolding walk boards for ease of installation and worker safety.

Key Features of Sunway Scaffolding Walk Board Roll Forming Machines

Sunway'in Scaffolding Walk Board Roll Forming Machines are designed with advanced features to meet the demands of modern manufacturing. Here’s what makes them stand out:

1. Yüksek Hassasiyetli Silindirler

The rollers are made of hardened, chrome-plated steel to ensure consistent shaping of walk boards with precise dimensions and reinforced edges.

2. Entegre Perforasyon Sistemi

An integrated punching system creates anti-slip perforations on the boards. The patterns can be customized to meet specific safety and design requirements.

3. Hidrolik Kesme Mekanizması

The cutting system ensures clean, burr-free edges, enhancing the quality of the finished product and reducing material waste.

4. Gelişmiş PLC Kontrol Sistemi

Bu Programlanabilir Mantık Denetleyicisi (PLC) system allows operators to adjust board lengths, perforation patterns, and production speeds easily via a touchscreen interface.

5. Yüksek Hızlı Üretim

Sunway machines are capable of producing scaffolding walk boards at speeds of Dakikada 10-20 metre, depending on the material and board specifications.

6. Malzeme Çok Yönlülüğü

Sunway makineleri, aşağıdakiler de dahil olmak üzere çeşitli malzemeleri işleyebilir:

- Galvanizli çelik

- Alüminyum

- Paslanmaz çelik

7. Güçlendirilmiş Kenar Şekillendirme

The machines ensure that the edges of the boards are reinforced for added strength and safety, making them ideal for heavy-duty applications.

8. Noise and Vibration Control

Sunway makineleri, daha güvenli ve daha konforlu bir çalışma ortamı sağlamak için gürültü sönümleme ve titreşim azaltma özellikleriyle tasarlanmıştır.

Explore these features in detail at Wuxi Sunway Makine and discover how Sunway’s solutions can transform your production process.

Types of Sunway Scaffolding Walk Board Roll Forming Machines

Sunway offers various types of machines tailored to meet the specific needs of scaffolding board manufacturers. Here’s an overview:

1. Standard Walk Board Machines

Ideal for manufacturers producing a single profile at high volumes, these machines are cost-effective and reliable.

2. Çok Profilli Makineler

Designed for flexibility, these machines can produce multiple profiles of scaffolding walk boards with quick tooling changes.

3. Yüksek Hızlı Makineler

Büyük ölçekli üretim için Sunway'in yüksek hızlı makineleri, kaliteden ödün vermeden maksimum verim sağlar.

4. Taşınabilir Rulo Şekillendirme Makineleri

Need to produce walk boards on-site? Sunway’s portable machines allow manufacturing directly at construction or project sites, reducing transportation costs.

Comparison Table: Types of Scaffolding Walk Board Roll Forming Machines

| Makine Tipi | Birincil Kullanım | Üretim Hızı | Fiyat Aralığı (USD) |

|---|---|---|---|

| Standart Makineler | Tek profilli üretim | 10-15 metre/dakika | $60,000–$90,000 |

| Çok Profilli Makineler | Esnek, çok tasarımlı kullanım | 10-20 metre/dakika | $90,000–$150,000+ |

| Yüksek Hızlı Makineler | Büyük ölçekli üretim | 15-25 metre/dakika | $120,000–$200,000 |

| Taşınabilir Makineler | Yerinde üretim | 5-15 metre/dakika | $50,000–$80,000 |

Pricing of Sunway Scaffolding Walk Board Roll Forming Machines

Bir fiyat İskele Yürüme Tahtası Rulo Şekillendirme Makinesi özelliklerine, üretim kapasitesine ve otomasyon düzeyine bağlıdır. İşte 2025 için genel bir fiyatlandırma kılavuzu:

- Standart Makineler: $60,000–$90,000

- Çok Profilli Makineler: $90,000–$150,000+

- Yüksek Hızlı Makineler: $120,000–$200,000

- Taşınabilir Makineler: $50,000–$80,000

Doğru fiyatlandırma ve finansman seçenekleri için iletişime geçin Wuxi Sunway Makine.

Automation Trends in Scaffolding Walk Board Roll Forming Machines

Automation is transforming the roll-forming industry, and Sunway is at the forefront of this revolution. Here are some key automation trends in 2025:

1. IoT Özellikli Akıllı Makineler

IoT integration allows manufacturers to monitor production metrics, machine performance, and maintenance needs in real-time. This ensures seamless operations and reduces downtime.

2. Kestirimci Bakım

AI-powered sensors analyze machine performance to predict potential failures. Proactive maintenance minimizes unexpected downtime and repair costs.

3. Tam Otomatik Üretim Hatları

Sunway’s automated machines handle every aspect of production, from coil feeding to forming, punching, cutting, and stacking. This reduces labor requirements and boosts efficiency.

4. Energy-Efficient Servo Systems

Servo-driven systems optimize energy usage, reduce operational costs, and enhance precision, making them eco-friendly and cost-effective.

Troubleshooting Common Issues in Scaffolding Walk Board Roll Forming Machines

En gelişmiş makineler bile zaman zaman sorunlarla karşılaşabilir. İşte sık karşılaşılan sorunların nasıl giderileceği:

1. Düzensiz Perforasyonlar

- Sebep: Misaligned punching dies or incorrect settings in the PLC system.

- Çözüm: Realign the dies and recalibrate the PLC system.

2. Malzeme Sıkışması

- Sebep: Yanlış bobin besleme veya makinede döküntü.

- Çözüm: Clean the feeding system, inspect the coil for defects, and ensure proper alignment.

3. Kenarlarda Çapaklar

- Sebep: Körelmiş kesme bıçakları.

- Çözüm: Sharpen or replace the cutting blades and ensure proper alignment of the cutting system.

4. Tutarsız Boyutlar

- Sebep: Hatalı PLC programlaması veya aşınmış silindirler.

- Çözüm: Verify and correct the PLC program. Inspect the rollers for wear and replace them if necessary.

Kalıcı sorunlar için şu adrese ulaşın Sunway'in uzman ekibi profesyonel yardım için.

FAQs About Sunway Scaffolding Walk Board Roll Forming Machines

| Soru | Cevap |

|---|---|

| Ortalama üretim hızı nedir? | Most machines can produce scaffolding walk boards at speeds of Dakikada 10-25 metre. |

| Bir makine birden fazla profil üretebilir mi? | Yes, multi-profile machines are designed to produce various board designs with quick tooling changes. |

| Bu makineler hangi malzemeleri işleyebilir? | Yaygın malzemeler arasında galvanizli çelik, alüminyum ve paslanmaz çelik bulunur. |

| Bu makineler vasıflı operatör gerektiriyor mu? | Hayır, Sunway'in PLC sistemleri kullanımı sezgisel ve kullanıcı dostu hale getirerek minimum eğitim gerektiriyor. |

| Bu makinelerin kullanım ömrü ne kadardır? | Doğru bakım ile Sunway makineleri uzun ömürlü olabilir 10-15 yıl veya daha fazla. |

| Finansman seçenekleri mevcut mu? | Evet, iletişime geçin Wuxi Sunway Makine finansman planları için. |

Advanced Automation Features of Scaffolding Walk Board Roll Forming Machines

Automation is no longer a luxury in manufacturing—it’s a necessity. Sunway’s Scaffolding Walk Board Roll Forming Machines integrate cutting-edge automation features that revolutionize how scaffolding walk boards are produced. Here’s how advanced automation enhances productivity and ensures consistency:

1. Smart IoT-Enabled Machines

Imagine having the ability to monitor your machine’s performance and production data from anywhere. With IoT (Nesnelerin İnterneti) integration, Sunway machines make this possible:

- Uzaktan İzleme: Operators can track production speed, output metrics, and material usage in real-time from their smartphones or computers.

- Maintenance Alerts: Receive early warnings about potential issues such as worn punching dies or low oil levels, minimizing unplanned downtime.

- Veri İçgörüleri: Historical data helps identify inefficiencies and optimize workflows for better performance.

IoT-enabled machines empower manufacturers to stay in control, even remotely.

2. Tam Otomatik Üretim Hatları

From material feeding to punching, forming, cutting, and stacking, Sunway’s fully automated machines handle every step of the production process seamlessly:

- Otomatik Bobin Besleme: The machine automatically loads and aligns metal coils, ensuring a smooth flow of material.

- Integrated Punching and Forming: The punching system creates anti-slip perforations, while the roll-forming system shapes the walk board simultaneously.

- Hydraulic Cutting and Stacking: The hydraulic cutting mechanism ensures precise lengths, while automated stacking prepares the boards for packaging or shipment.

Automation not only reduces labor costs but also ensures consistent quality and high production efficiency.

3. Uyarlanabilir Profil Değiştirme

Need to produce scaffolding planks with different dimensions or designs? Sunway machines make it easy:

- Hızlı Alet Değişimleri: Switch between profiles in under 15 minutes, minimizing downtime.

- Özelleştirilebilir Ayarlar: Adjust the board dimensions, perforation patterns, and reinforcement parameters using the touchscreen PLC interface.

- Flexible Production: Cater to diverse market demands without needing multiple machines.

With adaptive profile switching, you can take on new projects or clients with zero hassle.

4. Yapay Zeka ile Kestirimci Bakım

Why wait for a breakdown when you can prevent it? Sunway’s machines are equipped with AI-driven predictive maintenance systems:

- Gerçek Zamanlı İzleme: Sensors track the performance of critical components like rollers, punches, and motors.

- Arıza Tahmini: Advanced algorithms analyze sensor data to predict potential failures before they disrupt operations.

- Proaktif Onarımlar: Schedule maintenance during planned downtime, ensuring uninterrupted production.

Predictive maintenance can save manufacturers thousands of dollars in repair costs and lost production time.

5. Servo-Driven Technology

Servo systems offer unmatched precision and energy efficiency, making them a key feature of Sunway machines:

- Geliştirilmiş Doğruluk: Servo motors maintain consistent forming and cutting accuracy, even at high speeds.

- Enerji Verimliliği: Enerji tüketimini şu kadar azaltın 30% geleneksel hidrolik sistemlere kıyasla.

- Geliştirilmiş Dayanıklılık: Servo-driven machines experience less wear and tear, extending their operational life.

6. Customizable Perforation Patterns

Sunway machines allow for complete customization of perforation patterns:

- Anti-Slip Designs: Choose from standard or custom anti-slip patterns to meet your clients’ safety requirements.

- Ventilation Holes: Add ventilation features for boards used in specific applications like industrial maintenance or shipbuilding.

- Branding Options: Create unique perforation designs that include company logos or branding elements.

Visit Wuxi Sunway Makine to learn how automation can transform your scaffolding walk board production.

Environmental Impact of Scaffolding Walk Board Roll Forming Machines

Sustainability is becoming a priority for manufacturers worldwide, and Sunway machines are designed to align with this growing demand. Here’s how Scaffolding Walk Board Roll Forming Machines contribute to a greener, more sustainable future:

1. Malzeme Verimliliği

The roll-forming process is incredibly efficient, using nearly 100% of the raw material. Scrap is minimal, and any waste generated is often recyclable, reducing the overall environmental impact.

2. Energy Savings

Sunway machines are equipped with energy-efficient servo motors and optimized hydraulic systems, which reduce power consumption without compromising performance. This not only lowers operating costs but also minimizes your carbon footprint.

3. Geri Dönüştürülebilir Ürünler

Scaffolding walk boards are typically made from materials like galvanized steel, aluminum, or stainless steel—all of which are 100% recyclable. This ensures a sustainable lifecycle for your products.

4. Durable Design

Walk boards produced by Sunway machines are built to last, reducing the need for frequent replacements. Their durability minimizes resource consumption over time, making them an eco-friendly choice for construction and industrial applications.

5. Daha Temiz Üretim Süreci

Advanced automation reduces material wastage, rework, and emissions, ensuring a cleaner and more efficient production process. By investing in a Sunway machine, your operation can align with global sustainability goals.

Troubleshooting Common Issues in Scaffolding Walk Board Roll Forming Machines

Even with advanced features, occasional issues can arise in any machine. Here’s a guide to troubleshooting common problems to keep your production line running smoothly:

1. Yanlış Hizalanmış Perforasyonlar

- Sebep: Aşınmış zımbalama kalıpları veya hatalı PLC ayarları.

- Çözüm: Replace the punching dies and recalibrate the PLC system to ensure proper alignment.

2. Beslemede Malzeme Sıkışması

- Sebep: Improper coil feeding or debris in the feeding system.

- Çözüm: Clean the feeding mechanism and inspect the coil for defects or inconsistencies.

3. Uneven Board Profiles

- Sebep: Yanlış hizalanmış silindirler veya tutarsız malzeme besleme.

- Çözüm: Silindirleri yeniden hizalayın ve malzemenin uygun gerginlikle eşit şekilde beslendiğinden emin olun.

4. Burrs or Rough Edges

- Sebep: Kör veya hasarlı kesme bıçakları.

- Çözüm: Replace or sharpen the cutting blades. Verify that the cutting system is properly aligned.

5. Makine Duruş Süresi

- Sebep: İhmal edilen bakım veya kritik bileşenlerde tespit edilmeyen aşınma.

- Çözüm: Follow a strict maintenance schedule, including regular lubrication, cleaning, and part inspections. Leverage predictive maintenance tools if available.

Kalıcı sorunlar için iletişime geçin Sunway'in uzman destek ekibi profesyonel yardım için.

FAQs About Sunway Scaffolding Walk Board Roll Forming Machines

| Soru | Cevap |

|---|---|

| Ortalama üretim hızı nedir? | Sunway machines can produce scaffolding walk boards at speeds of Dakikada 10-25 metre. |

| Bir makine birden fazla profil üretebilir mi? | Yes, multi-profile machines are designed to produce various board designs with quick tooling changes. |

| Bu makineler hangi malzemeleri işleyebilir? | Yaygın malzemeler arasında galvanizli çelik, alüminyum ve paslanmaz çelik bulunur. |

| Bu makineler vasıflı operatör gerektiriyor mu? | No, Sunway’s user-friendly PLC systems require minimal training, making them accessible to all operators. |

| Bu makinelerin kullanım ömrü ne kadardır? | Doğru bakım ile Sunway makineleri uzun ömürlü olabilir 10-15 yıl veya daha fazla. |

| Finansman seçenekleri mevcut mu? | Evet, esnek finansman seçenekleri mevcuttur. İletişim Wuxi Sunway Makine detaylar için. |

Why Choose Wuxi Sunway Machinery for Scaffolding Walk Board Machines?

İşte ayarlayanlar Wuxi Sunway Makine apart in the roll-forming industry:

- Küresel İtibar: Asya, Avrupa, Afrika ve Amerika'daki üreticiler tarafından güvenilmektedir.

- Özel Çözümler: Customizable machines designed to meet your unique production needs.

- Birinci Sınıf Kalite: Built to international standards, ensuring precision, durability, and reliability.

- Kapsamlı Destek: From installation and training to maintenance and troubleshooting, Sunway offers unmatched customer service.

- Onlarca Yıllık Uzmanlık: With years of experience in roll-forming technology, Sunway is a name manufacturers trust.

Conclusion: Why Invest in a Sunway Scaffolding Walk Board Roll Forming Machine?

If you’re in the scaffolding or construction equipment industry, investing in a Sunway Scaffolding Walk Board Roll Forming Machine is a surefire way to elevate your production capabilities. With advanced automation, sustainability features, and exceptional build quality, Sunway machines are designed to meet the demands of modern manufacturing.

Üretiminizi bir üst seviyeye taşımaya hazır mısınız? İletişim Wuxi Sunway Makine today and let’s build a safer, more productive future together.