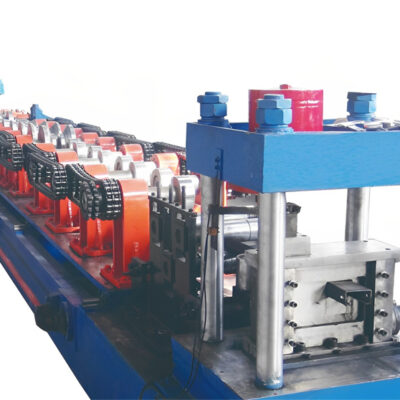

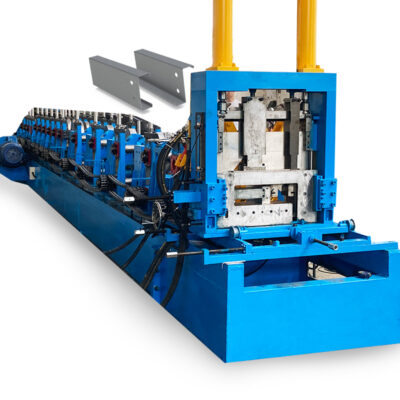

2 profile in 1 roll forming machine

2 profile in 1 roll forming machine Summary Material: Color steel, Galvanized coil Material Thickness: 0.4-1.5mm Forming Speed: 10-15m/min 2 profile in 1 roll forming machine Main Parts Manual Decoiler Feeding Guide Roll Forming System Hydraulic Cutting PLC Control System Run-out Table Working Flowing Decoiler— Guide–Roll Forming—- cutting–Run out table 2 profile in 1 roll forming…